All of us who have been in business awhile have either led or experienced the “methodology dejour”. We get all excited about something new we learn about and suddenly it is time to reinvent our companies around this new idea. And, then a week, or a month, or even a few days later, we are on to the next new thing.

All of us who have been in business awhile have either led or experienced the “methodology dejour”. We get all excited about something new we learn about and suddenly it is time to reinvent our companies around this new idea. And, then a week, or a month, or even a few days later, we are on to the next new thing.

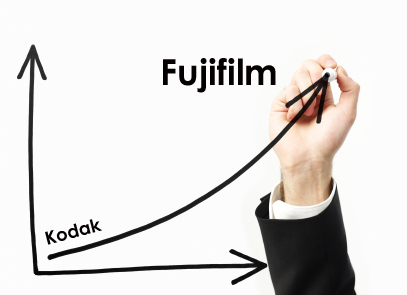

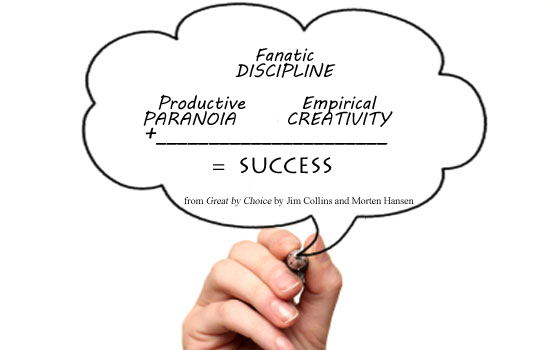

Sometimes though, something new comes along that is able to withstand the test of time. One such model is TQM, Total Quality Management. In the early 90’s Deming introduced the TQM model to U.S. manufacturing. This model included, among other things, the Japanese concept of Kaizen (continuous improvement) and what became a popular mantra called “business process redesign”. Today, there is a lot of talk about the failures of business process redesign. Too much change introduced at one time, simply doesn’t work – upwards of 75% of business process redesign projects fail.

On the other hand, Kaizen, or simply, continuous improvement has withstood the test of time in manufacturing and across all industries.

It’s a simple concept that goes like this, intentionally and continuously look for ways to innovate and improve your business processes. As leaders, ask your people to join in and look for ways to improve the business. Success will follow.

In Vistage we call the idea dujour risk, “DAV” (“Day after Vistage”) and remind our members to take only “one thing” away from each meeting and focus on incremental change, i.e. continuous improvement. The result… Vistage members outperform their industry peers.

What are you doing today, to foster a company culture of continuous improvement?

What financial benefits have come from your continuous improvement efforts?

What metrics do you have in place to measure the results of continuous improvement efforts in your business?

Elisa K. Spain

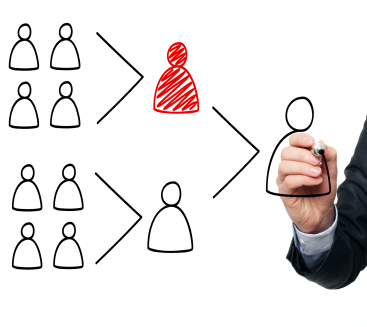

This month’s leadership quote: “Those who failed to oppose me… who readily agreed with me and accepted all my views…were those who did me the most injury.” -Napoleon Bonaparte

This month’s leadership quote: “Those who failed to oppose me… who readily agreed with me and accepted all my views…were those who did me the most injury.” -Napoleon Bonaparte

The initial results of my Pivot are excellent. I feel I have much greater clarity regarding the next 3-5 years..

The initial results of my Pivot are excellent. I feel I have much greater clarity regarding the next 3-5 years..  John Yerger

John Yerger